Pensasavulaiset ovat erikoismekanismeja, jotka on suunniteltu parantamaan tehtaan tehokkuutta. Ne ovat keskeisiä nopeuden lisäämiseksi tuotannossa sekä laadun parantamiseksi valmistettujen tuotteiden osalta. Katsotaan, miten pensasavulaiset auttavat tehdas ja keskustellaan myös siitä, miksi näitä työkaluja tarvitaan menestyksen saavuttamiseksi teollisuudessa.

Miten pensasavulaiset auttavat tuotannon kannustamisessa

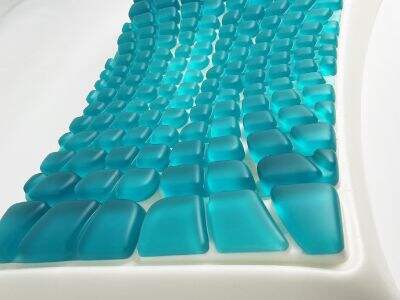

Pensasavulaiset kasvattavat tuottavuutta, joten tehtaat käyttävät niitä. Pensasta voi kertyä ja hidastaa kaikkea, joskus jopa valmistusprosessin aikana. Ja Geeli-alkuperäinen materiaali pensasta voi muuttua pullokohteiksi, jotka hidastavat tuotteiden virtausta järjestelmän kautta. Pensasavulaiset on suunniteltu hajottamaan tätä pensastaa, antaen tuotteille paremman ja nopeamman virtauksen. Nopeampi tuotantoprosessi mahdollistaa tehtaalle enemmän kappaletta valmistaa lyhyemmässä ajassa, mikä on olennaista pysyäksesi kilpailukykyisenä nykyisen nopeasti kehittyvän markkinoiden tilanteessa.

Miksi tehdasystäviä pensasavulaisia

Pensasavulaiset tarjoavat monia etuja, jotka Palohidastava silikoilu tekevät niistä erittäin arvokkaita tehtailla. Suurin edunsaaja on se, että ne vähentävät jätettä. Kumous syntyy usein tuotannossa, mikä voi kiinnittää osan tuotteesta itseseen. Tämä johtaa aineksien hukkaamiseen, mikä myöhemmin nostaa tehtaan kustannuksia. Kumousoittimien avulla kumous rikottaisiin, jotta vapautettaisiin sidottu tuote. Tämä antaa tehtaalle mahdollisuuden hyödyntää kaikki resurssit, joita se hallitsee, käyttääkseen niitä täysimääräisesti ja säästääkseen rahaa kuluvan ajan myötä.

Penssimurtoimet ovat myös hyödyllisiä, koska ne auttavat parantamaan valmistettavien tuotteiden laadua. Penssi on monien valmistusprosessien sivutuote, ja näissä tapauksissa se voi aiheuttaa puutteita lopputuotteessa, mikä johtaa huonoon yhtenäisyyteen. Penssimurtaimet avauttavat penssiä niin, että sen osat hajottuvat, mikä lopulta antaa tasaisemman ja laadukkaamman tuotteen. Aloilla, joilla laatu on ratkaisevan tärkeää, kuten lääkeyhtiöiden valmistuksessa ja ruokantuotannossa, tämä on erityisen tärkeää. Yhtenäisten ja luotettavien tuotteiden saaminen on erityisen keskeistä asiakkaiden tyytyväisyyden ja turvallisuuden kannalta näillä aloilla.

Miten tehdä tehtaista tehokkaampia

Korkeampi tehokkuus on modernien tehtaaiten yhteinen nimittäjä, ja penssimurtaimet edistävät tehokkuuden kasvua monilla eri alueilla. Polyeteripolyoli ne vähentävät pysähtymisaikoja. Pena voi jatkua tuotannossa, ja se tuhoaa koneita, kun prosessi pysäytetään penan kasvuun, mikä johtaa hukkaan menetettyyn aikaan ja potentiaalisiin tulojen menetyksiin. Penanpoistajat ovat tarkoitettu estämään näitä esteitä ja auttavat pitämään tuotantovirtaa keskeytymättömänä. Tämä mahdollistaa tehtaalle vakionnetun työvirran ja parantaa yleistä tuottavuutta.

Penanpoistajat voivat myös vähentää energiakustannuksia, toiseksi. Joten kun pena on olemassa, koneet ja pomput täytyy työskennellä paljon kovemmin tuotteiden päästämiseksi järjestelmän läpi. Tämä lisätyö voi johtaa korkeampaan energiahluttiin ja alennettuun tehokkuuteen. Penanpoistajat vähentävät energiakuljetusta ja lisäävät yleistä tehokkuutta, koska ne auttavat koneita viemään tuotteita helpommin eteenpäin purkamalla pena.

Välttämättömät työkalut menestyksen saavuttamiseksi

Pensasavuttimet ovat todellakin arvokkaita työkaluja tehtaiksi, jotka haluavat onnistuneita toimintoja. Ne ovat keskeisiä tuotannon edistämiseen, jätteen poistamiseen ja tuotteen laadun sekä tehokkuuden parantamiseen. Pensasavuttimet tunnetaan olevan välttämättömiä laitteita valmistusalalle; ne voivat auttaa tehtaita välttämään lukemattomia pensaan liittyviä ongelmia, joita seuraa taloudellisia ja kilpailukykyisiä haittoja.

SANYING: Paras valinta pensasavuttimiin

Ymmärtäen pensasavuttimien tarpeen teollisuusprosesseissa SANYINGilla on omistautunut tiimi, joka tuottaa vain pensasavuttimia. Myymme kaikkia tyyppisiä pensasavuttimia, jotta voimme täyttää kaikki asiakkaidemme tarpeet. FOAM-savuttaja on suunniteltu olemaan tehokas, luotettava ja tehokas; savuttimemme auttavat varmistamaan, että voimme antaa asiakkaillemme maksimaalisen läpimäärän ja yhtenäisyyden tuotantoprosessissa.

Pensasavuttimet: Parantavat suorituskykyä ja laatua

Lopuksi huomaa, että puuvillajauheet johtavat parempaan suorituskykyyn ja tuotantoon. Nämä työkalut varmistelevat, että tuotteet voidaan käsitellä puuvillalla nopeammin, mikä auttaa luomaan tulot, kun ne hajoittavat materiaalin. Lisäksi jätteen minimoinnin ohella ne säästvät yrityksille merkittäviä summia pitkälläjännällä.

Näiden edut lisäksi puuvillajauheet usein parantavat valmistettavan tuotteen peruslaatua. Ne varmistelevat, että lopulliset tuotteet ovat tasapainoisia ja korkeakuntoisia. Ruokateollisuuden ja lääkealan kaltaisissa sektoreissa, joissa kuluttajien terveys ja hyvinvointi riippuu tuotteiden laadusta, tämä on erityisen tärkeää.

Johtopäätös

Pensasavaintaja on siten ratkaiseva työkalu kaikille teollisuudenaloille, jotka haluavat olla parhaassa muodossaan. Ne ovat yleisiä maksimaalisen tuotannon saavuttamiseksi, jätteen vähentämiseksi, tuotteen laadun parantamiseksi ja tehokkuuden korottamiseksi. SANYING pyrkii valmistamaan laajaa valikoimaa korkealaatuisia pensasavaintoja täyttääkseen asiakkaidemme monipuoliset tarpeet. Jos haluat saada lisätietoja siitä, miten voimme auttaa sinua saavuttamaan tuotantotavoitteesi, otathan meihin yhteyttä tänään!