Sponge is a kind of polyurethane foam, and it is also a kind of soft polyurethane foam.

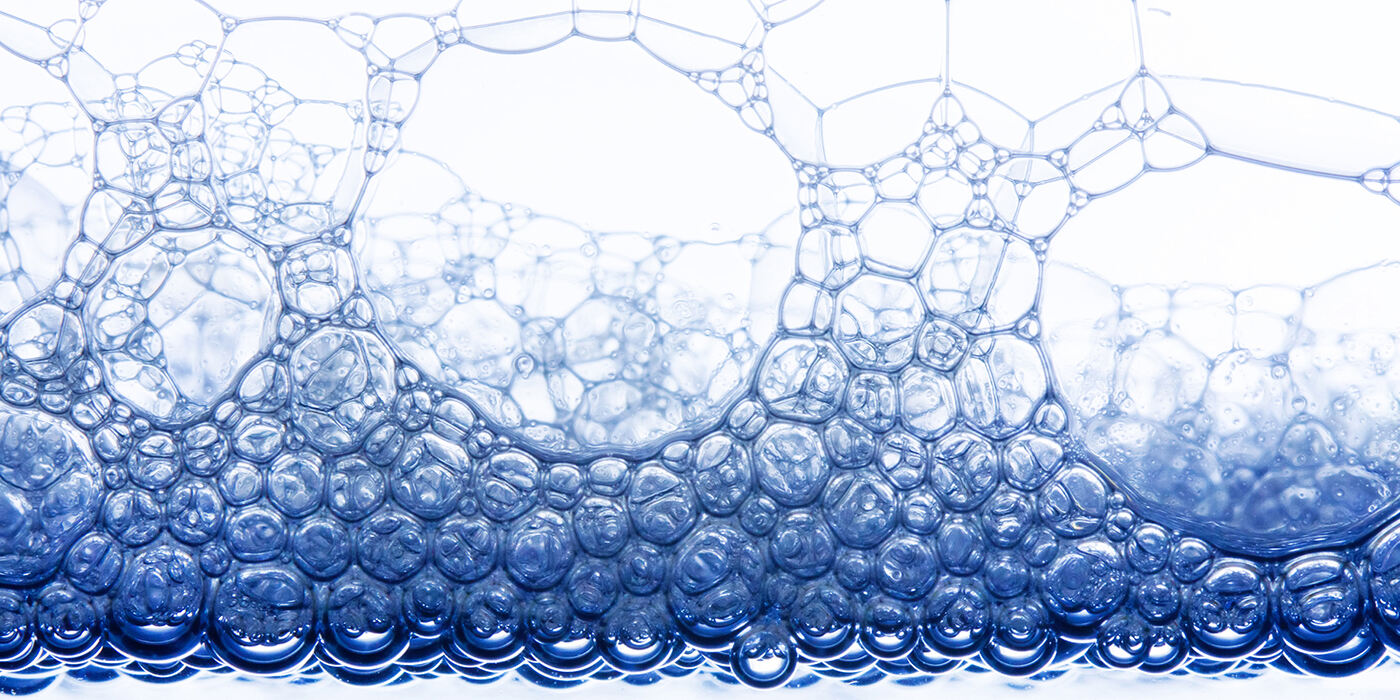

Because of its porous honeycomb structure, the sponge has excellent characteristics of softness, water absorption, elasticity and water resistance, which make it widely used in sofa, clothing, mattress, flexible packaging and other industries.

The main raw materials of sponges:

1. Organic isocyanate: the most commonly used isocyanate is methylene diisocyanate, or TDI for short. There are two isomers, namely 4murTDIJI 6murTDI.

In the production of sponges, 4-TDI accounts for 80% of the total.

2. Polyether polyol: the sponge mostly uses polyether propylene glycol and polyether glycerol, which has less function (2-3), low hydroxyl value and high molecular weight.

The molecular formula is CH3-CHO (C3H6O) m (C2H4O) nH CH2O (C3H6O) m (C2H4O) nH.

3. Catalyst: the catalysts that can promote the reaction of polyether polyol and isocyanate to make chain growth are stannous octanoate and dibutyltin.

The catalysts that promote the crosslinking reaction and the CO2 gas released from the reaction between isocyanate and water are triethanolamine, triethylenediamine, triethylamine and so on.

4, foam stabilizer (foam stabilizer): commonly used silicone foam stabilizer, mainly using silicon-carbon bond Si-C copolymer, the dosage is about 0.5% 5%.

5. Foaming agents for external use: fluorocarbons with low boiling point are commonly used, such as fluorotrichloromethane (Fmur11).

Because it is not environmentally friendly, cyclopentane is generally used instead of Fmur11, or dichloromethane, and the effect is good.

6. Water: in the production of sponge, water is indispensable. Water reacts with TDI to release CO2 gas, which plays a role in chain growth.